Roll forming machine :

- Specification :

The Roll Forming Line has Following Advange :

• Unlimited Length. • Any Complicated bend not possible on Press Brake. • High Rate of Production. • Repeatative Accuracy of Profile. • Low cost of Products.

-

Working :

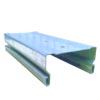

- Automotive : Chasis, Angle, Channel, Side Panel

- Electrical : Cable Tray, Strut Channel, T Grid

- Construction : Z Perlin, Door Frame, Window Frame, Roofing Sheet, W Section, Fancing

- Material Handling :False Ceiling, Pop Ceiling, Lighting Fixtures

- Furniture : Drawer Channel, IT Rack Section, Storage System Section

- Working Process :

-

Forming is the Process to bend the sheet / strip as per design or drawing. The blank of sheet is passed between roll former to achieve the desired shape without any variation or change in thickness. Wide range of machine helps customer to select the machine as per job requirement. The line is supplied with attachments which facilitate to get finished products at end with desired length.

- • Profile Cutting after formed

- • Post Punching

- • Edge Bending

- • Multi fold operation

- Technical Specification :

Description Model NumberUnitGT-1GT-2GT-3GT-4GT-5GT-6GT-7GT-8GT-9In Put Strip Width M.M.150150250250350350350500500Max. Strip Thickness M.M.121.22.51341.53Horizontal Center Distance M.M.185215185315205365465365465Min. Vertical Center Distance M.M.95115100115100150150115150Max. Vertical Center Distance M.M.125165125165125215265165215Roll Shaft Diameter M.M.354545505060706070Motor Capacity H.P.2537.5310151012.5Description Model NumberUnitGT-10GT-11GT-12GT-13GT-14GT-15GT-16GT-17GT-18In Put Strip Width M.M.50060075075010001000125012501400Max. Strip Thickness M.M.51.51.531.531.532Horizontal Center Distance M.M.495415415415465465535535535Min. Vertical Center Distance M.M.170115150170145170170170175Max. Vertical Center Distance M.M.295165215295215305215305335Roll Shaft Diameter M.M.85657085758590105115Motor Capacity H.P.301012.5251520203040